- GST No. 09AAHCS2336R1ZP

- Send SMS

- Send Email

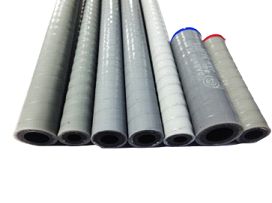

Hoses

Leading Manufacturers, Exporters and Trader of AEM Hoses, Fuel Hoses, EPDM Hoses and Silicone Hoses from Meerut.

| Business Type | Manufacturer, Exporter, Trader |

Ethylene acrylic rubber is a mixed polymer of ethylene and methyl acrylate, with the addition of a small amount of a carboxylate crosslinking monomer. The combination of ethylene and methyl acrylate gives the rubber its excellent thermal stability, while its resistance to media such as oils and fats is due to the polarity of the methyl acrylate commoner. A higher acrylate content improves resistance to oils, but reduces low-temperature flexibility.

AEM Application

- Turbocharger hoses and other hose applications

- Blow-by gas and diesel particle filter sensor sheaths

- Air management elements

- Oil- and heat-resistant vibration dampers

- Engine and transmission seals

- Cylinder head cover gaskets

- Oil filter and oil sump gaskets

- Shift pistons

AEM Main Properties

- Excellent weather and ozone resistance

- Very good heat and chemical resistance

- Resistant to most oils and lubricants (even those containing aggressive additives)

- Low compression set

- Good for low-temperature applications

- Thermal application range: -40 to +150°C, up to 175°C for short periods

| Business Type | Manufacturer, Exporter, Trader |

| Temp. Range, °C | -50 / 200 |

| Compression Set | Fair/Good |

| Strength Properties | Fair |

| Low Temp. Prop. | Excellent |

| Abrasion Resist | Poor |

| Gas Permeability | Fair |

| Weather Resist. | Excellent |

| Water Resistance | Excellent |

| Ozone Resistance | Excellent |

| Mineral Oil Resist. | Excellent |

| Chemical Resist. | Fair/Good |

| Flame Resistance | Excellent |

| Heat Resistance | Excellent |

Fluorosilicone is a widely used elastomer that can be compounded to meet a wide range of applications. The mechanical and physical properties are very similar to silicone rubber. However, fluorosilicone offers improved fuel and mineral oil resistance but poor hot air resistance when compared with silicone. This material is widely used in semiconductor Ashing equipment for its resistance to oxygen plasma.

| Business Type | Manufacturer, Exporter, Trader |

EPDM stands for Ethylene Propylene Diene Monomer, a synthetic rubber used in a range of applications. EPDM is used most commonly used in the automotive and construction industries for various seals due to its excellent resistance to environmental factors such as Ozone, UV and general weathering. Typical applications of EPDM are window and door seals (glazing), waterproofing sheets and electrical gaskets.

EPDM Application

- Mandrel formed drain tubes Pressure switch tubing

- Panel gaskets and seals

- Weather stripping and seals

- Window spacers

- Door, window, and trunk seals

- O-rings

- Air Filter Hoses(Plain n Ribbed)

- Hoses

- Grommets

- Shock Absorber

- Dust Covers

- Belts

- Electrical insulation and stinger covers

EPDM Benefits and Advantages

- Resistance to UV exposure, ozone, aging, weathering, and many chemicals – great for outdoor applications.

- Stability in high and low temperatures – a general purpose EPDM material can be used in an environment where the temperature range is from -45⁰C to 150⁰C.

- Low electrical conductivity.

- Steam and water resistant.

- Can be fabricated in a variety of ways, which includes custom moulded and extruded parts.

- Long-term part lifespan allows for fewer replacement parts, saving money in the long run.

EPDM Moulding Processes

- Transfer Moulding

- Injection Moulding

- Compression Moulding

Sizes

- ID1 (mm) : As per Customer Requirement

- ID2 (mm) : As per Customer Requirement

- Length(mm) : As per Customer Requirement

- Wallthickness(mm) : As per Customer Requirement

- Ply : As per Customer Requirement or As per Burst Pressure required

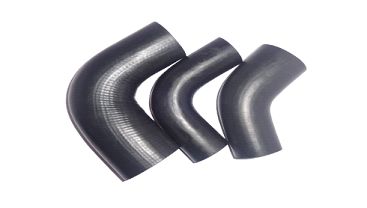

| Business Type | Manufacturer, Exporter, Trader |

| Uses | Coolant, Turbocharger, CAC, Air, Air with Oil Vapours, Air with Fuel Vapours, etc. |

| Working Temperature | -60ºC to + 300ºC. |

Features:

- Custom ply Polyester/Aramid/Cotton/ Kevlar/knitted fabric reinforcement.

- Custom ply configuration to meet desired flexibility & Burst pressure, Vacuum Pressure and Impulse Resistance Requirement.

- Material properties & performance as per SAE J20, SAE J30,SGH 1801 or as any specified customer standard.

- Excellent Ozone and UV Resistance.

Sizes :

- ID1 (mm): As per Customer Requirement

- ID2 (mm): As per Customer Requirement

- Length (mm) : As per Customer Requirement

- Wallthickness (mm): As per Customer Requirement

- Ply : As per Customer Requirement or As per Burst Pressure required