- GST No. 09AAHCS2336R1ZP

- Send SMS

- Send Email

| Business Type | Manufacturer, Exporter, Trader |

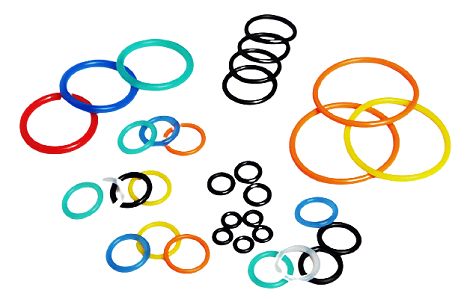

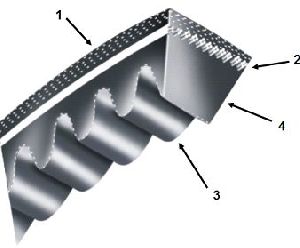

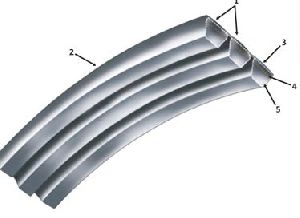

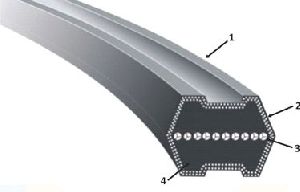

Rubber is known as Thermoset elastomer. Rubber parts are extensively used in several industries as they are capable of offering both flexibility and durability. Rubber products have decent thermal and insulation characteristics.

Application

- Mandrel formed drain tubes

- Pressure switch tubing

- Panel gaskets and seals

- O-rings

- Air Filter Hoses(Plain n Ribbed)

- Hoses

- Grommets

- Shock Absorber

- Dust Covers

- Electrical insulation and stinger covers

Benefits and Advantages

- Resistance to UV exposure, ozone, aging, weathering, and many chemicals – great for outdoor applications.

- Stability in high and low Temperature.

- Steam and water resistant.

- Can be fabricated in a variety of ways, which includes custom moulded and extruded parts.

- Long-term part lifespan allows for fewer replacement parts, saving money in the long run.

Moulding Processes

- Transfer Moulding

- Injection Moulding

- Compression Moulding

Used Rubber

EPDM, NBR, HNBR, Silicone, Viton, Neoprene, etc.

Looking for "Moulded Rubber Parts" ?

Piece